Concept Overview

Concept Overview

Engineering LOCK+LOAD is comprised of two pieces; a panel, and a counterfort that are assembled into a “Modular Cantilever”. The assembled LOCK+LOAD module has a face area of 3.5 sf (0.32sm) and weighs some 130lbs or < 40lbs/sf (59kg) 185kg/sm making it the largest manually installed retaining wall facing on the market.

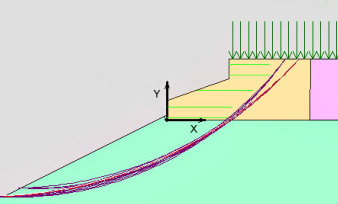

LOCK+LOAD is used by itself for retaining walls in the five foot high range. For taller retaining walls, LOCK+LOAD becomes a facing element for various types of retaining structures.

LOCK+LOAD has been utilized extensively in mechanically stabilized earth walls. These MSE walls can be designed by any code-approved procedure (AASHTO, NCMA etc.). All design procedures consider the particulars of the facing elements used for the wall. These facing element design considerations include; component strength, durability, and connection mechanism.

LOCK+LOAD elements are wet cast from 5500psi (42mpa) polyfiber reinforced concrete. Both elements have steel reinforcement. The panel reinforcement is made of corrosion resistant steel that extends out of the panel back to provide a connecting loop for attachment to the counterfort.

Engineering Considerations for LOCK+LOAD (assembled unit, panel hooked over the counterfort

Strength of Panel

LOCK+LOAD tests the product by pulling the panel into the soil mass using the counterfort to test loop embedment strength. The steel connection loops pull out of the concrete panel at a value of ~6000 lbs (2727 kg) and provide a 75 year or 100 years design life, using standard AASHTO corrosion criteria for the connecting steel. Standard LOCK+LOAD products have been tested and certified lab test reports are.

Strength of Counterfort (panel soil reinforcement)

The counterfort is embedded into the compacted fill, immediately behind the face panel. LOCK+LOAD has tested the embedment of the counterfort with various different confining stresses. The fill in the counterfort zone is currently specified as clean crushed rock compacted to a specific performance specification. Tests show that the counterfort pullout resistance develops over 6 times faster than the driving forces thus ensuring a large safety factor for counterfort connection to the soil mass. These tests are also available upon request.

Connection Strength of Primary Soil Reinforcement

The final connection consideration is the connection of the primary soil reinforcement (grid, wire mat, etc.) into the zone of backfill overlapping the counterfort. Since this is the crushed rock zone these connection values can be easily calculated from the Ci (coefficient of interaction) values provided by reinforcement manufactures. To verify these calculated values LOCK+LOAD has test data from several combinations of primary soil reinforcement types and manufacturers. In all cases the tested capacities exceed the calculated connection capacities.

Since the strength of the counterfort and panel are never critical and pullout capacity increases rapidly with rising “overburden” stresses in retaining walls, “Connection” strength is rarely a critical design consideration for LOCK+LOAD fascias. Current computer programs calculate the connection of the LOCK+LOAD modules to the soil reinforcement as the pullout capacity generated by the primary soil reinforcement from the “crushed stone” zone overlapping the counterfort in their design.

While LOCK+LOAD can be used on walls designed by numerous methods the MSEW3 & ReSSA3 software available from Adama Engineering (www.Geoprograms.com) are most often used with the test data provided.

Drawings Continued

DOT 5C F-STYLE BARRIER

DOT 5C F-Style Barrier- AutoCAD

DOT 6A Horizontal Obstruction – AutoCAD

DOT 6B HORIZONTAL OBSTRUCTION

DOT 6B Horizontal Obstruction – AutoCAD

DOT 7 Vertical Obstruction – AutoCAD

DOT 7B VERTICAL OBSTRUCTION

DOT 7B Vertical Obstruction

DOT 9 Foundation Pad – AutoCAD

DOT 10A SIDEWALK

DOT 10A Sidewalk – AutoCAD

DOT 11 SWALE

DOT 11 Swale – AutoCAD